In the dynamic landscape of food processing technology, the retort food machine stands out as a pivotal part in making certain food durability, safety, and top quality. The procedure not only sterilizes the food yet likewise preserves its taste and texture, making it a recommended option for food manufacturers worldwide.

The convenience of retort machines allows food processors to package a large array of items, including vegetables, meats, and ready-to-eat meals, successfully providing to the varied choices of customers. With the advancement of food production equipment, modern-day retort machines are crafted for energy, efficiency, and uniformity savings, making them important in today's competitive market.

The global food processing equipment manufacturers continually introduce to boost the performance of retort machines. These improvements not only purpose to enhance the sterilization process however likewise to decrease water and energy intake, consequently reducing environmental influence. For services wanting to purchase a retort machine, it's vital to think about factors such as throughput capacity, temperature level control, and the particular needs of the foodstuff included. Comprehending these variables can lead to far better decision-making and eventually higher item high quality.

Safety and security standards in the food market are extremely important, and using a retort sterilizer helps meet strenuous wellness laws by guaranteeing that all pathogens are effectively removed. The usage of pressure autoclaves, which are similar to retort machines but often used in a wider range of applications outside food processing, emphasizes the adaptability of autoclave technology as a whole.

An arising pattern amongst mixer is the need for automation within the retort and packaging processes. Industries are progressively transforming to totally automated systems that integrate perfectly with retort machines, enhancing production performance and reducing labor costs. This change not just adds to more regular product quality yet also permits manufacturers to react promptly to market adjustments. As consumer preferences change towards ease and ready-to-eat meals, the relevance of effective food processing equipment can not be overstated, and retort machines play a necessary duty in meeting this demand.

From small artisanal procedures to extensive commercial kitchens, the retort machine has become synonymous with food safety and conservation. The retort process warranties that also as food production ranges, safety and security and honesty are not jeopardized.

Looking for manufacturers with a tested track record is beneficial when taking into consideration getting a retort autoclave or any type of industrial autoclave for sale. Looking into recognized players in the food processing equipment market allows buyers to contrast functions, reliability, and assistance services. Speaking with reviews and testimonials can lead to notified buying choices. Retort machines represent a long-lasting financial investment for food manufacturers; hence, choosing a top quality machine is paramount in accomplishing continual functional success.

Furthermore, ecological sustainability is coming to be an essential aspect of food production, with numerous manufacturers seeking greener processing techniques. Retort innovation has also adapted to these demands, with developments concentrated on power effectiveness and sustainable materials. Innovative designs reduce the carbon impact connected with food processing while preserving high standards of food safety. As consumers increasingly prefer sustainably created products, companies equipped with these environmentally friendly retort machines will locate a substantial benefit in the industry.

Food security and guideline companies internationally support for making use of trusted processing equipment to battle foodborne illnesses, offering an additional inspiration for business to embrace retort sterilization innovation. Contemporary retort machines frequently integrate sophisticated monitoring systems that track and record processing problems in real-time, boosting traceability and liability within the food supply chain.

The technical innovations within retort sterilizers and check here autoclaves have actually made it possible to enhance the production process substantially. Advanced sensors and software program read more allow drivers to keep track of numerous processes concurrently and make quick changes as required, boosting operational adaptability.

Incorporating retort machines into food processing equipment financial investments mirrors a commitment to high quality that can establish a firm apart from its rivals. Customers today are knowledgeable and acutely mindful of the food processing methods behind their purchases. As a result, using modern technology that assures safety and security and top quality can be a solid marketing factor. In addition, the capability to supply openness relating to processing techniques, consisting of making use of retort sterilization, can develop customer loyalty and boost brand name track record.

In recap, the duty of retort food machines and autoclaves in modern food processing can not be overemphasized. These machines are crucial in providing secure, top quality food products that fulfill the high standards customers expect. As modern technology remains to progress, the field of food processing is established to successfully deal with new difficulties while adjusting to shifting consumer needs. From efficiency and security to sustainability and automation, retort machines and their sustaining modern technology develop the foundation of a dependable and forward-thinking food production system. Whether it is large industrial autoclaves or specialized food retort machines, the continued investment in this innovation will certainly drive the landscape of food security and top quality criteria right into the future.

Neve Campbell Then & Now!

Neve Campbell Then & Now! Amanda Bynes Then & Now!

Amanda Bynes Then & Now! Patrick Renna Then & Now!

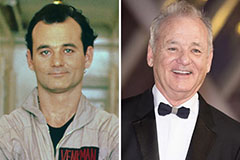

Patrick Renna Then & Now! Bill Murray Then & Now!

Bill Murray Then & Now! Ricky Schroder Then & Now!

Ricky Schroder Then & Now!